Do you know by knowing the ins and outs of the supply chain, you can double your profit and meet customers’ needs? Supply chain management is the very first step of the success ladder for your business. It gives you the entire control of your product lifecycle, from the day it was just a raw material to the day it reached your customers.

However, like many, if you also see each stage of the supply chain control process as an individual part rather than as a big picture, you are making a big mistake. Each part is important and helps in managing the entire supply chain.

What is Supply Chain Management?

Think of it as a relay race where everyone is doing their job perfectly and working together to win the race. The only difference is money, information, materials, and people are involved in the real world of supply chain management (SCM).

It’s like managing all the moving parts that get a product from the factory to the doorstep of your customers. Every part has to be in sync otherwise the whole purpose of the supply chain is defeated.

A broken supply chain brings direct loss to your business and customers. Therefore, managing each part effectively is very important.

How Does Supply Chain Management Work?

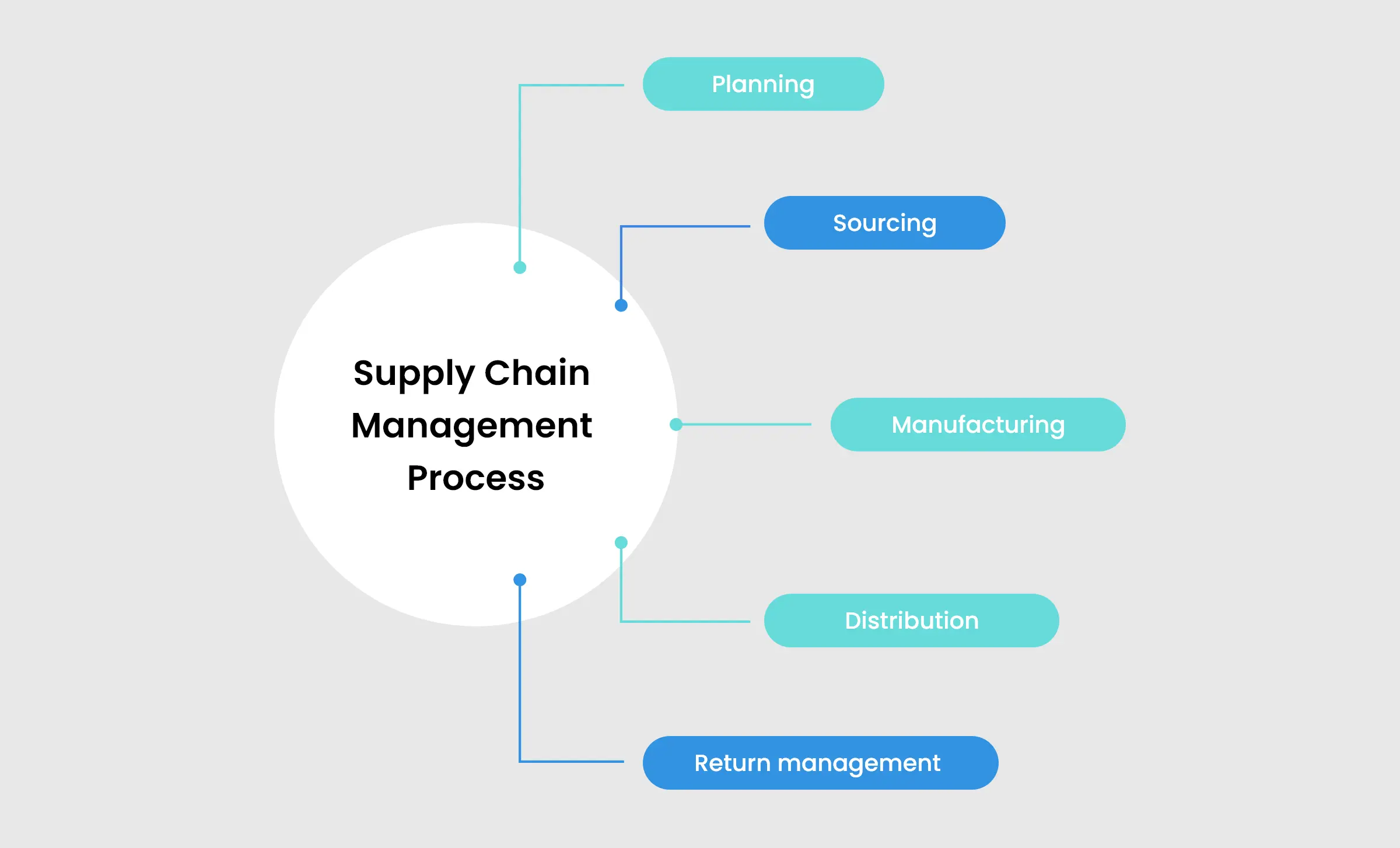

To understand the first step in the supply chain management process, you must understand the multiple steps or stages involved.

1. Planning

This is the blueprint stage where the matching of supply and demand is done. The supply chain control process plays a crucial role in ensuring this alignment is effective and efficient. The core purpose is to identify the raw materials you would need to manufacture a product.

The amount of raw material needed is also decided at this stage. Not just raw materials, manpower, and budget is also considered. This marks the first step in the supply chain, laying the groundwork for successful execution.

Ignoring price fluctuations during the planning stage can bring huge losses and affect other stages. Therefore, keep tabs on the current pricing and also look for alternative materials for cost control.

Also Read: How Manufacturers Can Tackle Raw Material Cost Fluctuations?

2. Sourcing

Once you know the initial requirements, find the best suppliers for raw materials and parts. You may come across hundreds of vendors with different price rates. Carefully selecting the vendor will make all the difference to the later stages of your supply chain.

But finding the best vendor is not the only job to do. You should invest in making good relationships with the suppliers. Price negotiation, ordering, receiving, monitoring suppliers and inventories, and raw material handling need to be taken care of.

3. Manufacturing or Producing

Now happens the real work where your product starts taking shape. Different parts of the product are assembled, which is then tested, quality-checked, and packed for delivery. This stage is a critical step in the supply chain management process, ensuring that every component meets quality standards.

Be mindful at this stage as production also comes with a lot of waste. By identifying the opportunities, you can minimize waste and produce efficient products.

4. Distribution

It’s time to deliver products to their real owners i.e. customers. A lot of things need to be taken care of at this stage of supply chain management. For example, logistics and warehouse management, order processing, invoice generation, and payments.

Effective product distribution means each of these stages is working smoothly. Unexpected delivery hurdles may occur due to environmental reasons or faults in vehicles. Your supply chain must be ready to handle them.

5. Return Management

Once the product reaches the customers, don’t think of it as the end of supply chain management process.

What if customers do not like the product or want to return? This stage is an integral part of the supply chain control process, often referred to as reverse logistics.

Besides making it easier for customers to return their orders, there is a process for refunds and collecting customers’ feedback as well. The importance of supply chain planning and control at this stage cannot be ignored, as it helps maintain customer satisfaction and loyalty.

Smooth working of each of these stages is important to run your business smoothly and find ways to win your customers.

Why is Supply Chain Management Important?

For Finding Cost-Cutting Opportunities

One of the primary reasons for effectively managing the supply chain is to reduce costs. There are different cost-cutting opportunities.

By identifying them, you can save money and also fine-tune the processes used in procurement, production, and logistics. This flexibility and lean nature of the supply chain management help reduce wastage associated with inventory.

To Predict Stock Shortages

Running out of stocks is a common challenge that many businesses want to overcome. With an effective supply chain management strategy, you can get insights of your inventory and predict early when the product will go out of stock.

To Provide Better Quality and Customer Satisfaction

A proper running supply chain management guarantees good quality products and on-time delivery guarantee. It increases customers’ satisfaction and positively influences customer loyalty, which is valuable for the long-term success of your business.

To Gain Competitive Advantage

Today, the ability to quickly respond to changes in consumer demand and market conditions becomes a company’s competitive advantage. A swift supply chain management makes your business flexible and quick to adopt those changes. It also ensures faster re-entry of your products.

For Risk Management

Supply chains also face several risks like natural disasters, political instability, or failure of suppliers. Effective SCM helps in quick identification of the possible risks and developing emergency plans to mitigate them. This allows you to operate without much loss and take remedial measures at the right time.

While these advantages of effective SCM are hard to ignore, they are not possible without modern-day software. From planning to managing returns, supply chain management software helps you at every stage. And with a dashboard feature, you get a clear picture of your supply chain with just one click. It’s like adding the real value to your supply chain.