In today’s fiercely competitive manufacturing world, staying profitable boils down to two non-negotiables: running efficiently and keeping costs in check. That’s exactly where Enterprise Resource Planning (ERP) systems and dedicated costing tools step in. Both are designed to help manufacturers manage and reduce costs, but they go about it in very different ways.

ERPs are built to centralize data and streamline workflows across procurement, production, inventory, and finance. On the other hand, costing tools are specifically designed for precise, product-level cost calculations, simulations, and informed sourcing decisions.

But here’s where many manufacturers hit a fork in the road: ERP vendors often tout built-in costing features. So, finance and procurement leaders naturally ask, do we really need a separate costing tool if our ERP already handles costing?

How ERP Helps in Costing

ERPs are the backbone of most manufacturing setups. They are designed to unify everything, from procurement to production to finance, into a single, integrated platform. When it comes to costing, they provide the foundational tools manufacturers need to monitor and manage spending at a broader level.

Here’s how ERP systems support costing:

- Standard Costing & Actual Costing: ERPs allow you to set standard costs for materials, labor, and overhead. These can then be compared to actual costs to identify discrepancies. It gives finance teams a quick pulse on where things are going off track.

- BOM Cost Rollups: ERPs can automatically calculate the total cost of a product by summing up the Bill of Materials (BOM), raw materials, machine usage, labor, and overhead included.

- Inventory Valuation: They handle costing methods like FIFO, LIFO, or weighted average to help finance teams accurately value inventory and determine the cost of goods sold (COGS).

- Cost Allocation & Budgeting: You can allocate costs to departments or specific projects, supporting better planning and budget control.

- Compliance & Audit-Readiness: ERPs keep a clear record of all transactions, making it easier to stay compliant and pass audits without headaches.

Features of ERP

- Financial Management Modules: Full accounting capabilities, including general ledger, AR/AP, asset management, and reporting, vital for cash flow and compliance.

- Procurement & Inventory Management: Automates everything from purchase orders to stock tracking, helping control inventory levels and reduce overhead.

- Production Planning & MRP: Manages material and labor requirements, aligning production schedules with forecasts to avoid delays.

- Standard/Actual Costing & Variance Tracking: Basic costing functionality with reports to show where planned vs. actual costs diverge.

- Regulatory Compliance & Reporting: Supports tax and accounting standards with full traceability and workflows.

- System Integration: Connects seamlessly across your CRM, HRMS, and supply chain tools, acting as the data nerve centre.

Pros of ERP

- Centralized System

- Standardized Costing

- Inventory & Resource Planning

- Audit & Compliance Ready

Cons of ERP

- Limited Costing Depth

- Rigid for Scenario Planning

- Lacks Intelligence Layer

- Slow to Customize

ERPs are built for reliability and control, not speed or flexibility. Their costing capabilities are often rigid and limited to historical tracking rather than forward-looking decision support. That’s where costing tools come into the picture.

How Costing Tools Like Cost It Right Help

While your ERP shows what happened financially, a costing tool like Cost It Right helps you take charge of what happens next. It’s all about flexibility, speed, and precision, especially when you are facing rapid product changes, supply chain volatility, or pressure to protect your margins.

Here’s what a costing tool brings to the table:

- Granular, Item-Level Costing: Costing tools calculate costs down to the smallest component, factoring in material prices, tooling, machine usage, labor rates, overheads, and logistics. This enables accurate analysis of product profitability at the SKU level.

- AI-Powered Should-Cost Estimation: Tools use AI to generate highly accurate should-cost models. These models predict the cost of a part or product based on design attributes, manufacturing complexity, and market conditions, empowering procurement teams to negotiate more effectively with suppliers.

- Real-Time Scenario Planning: Want to see how a 15% spike in aluminium prices affects your margins? Or what switching suppliers would do to your costs? You can run those simulations instantly, no impact on your ERP data.

- Cross-Functional Collaboration: These tools provide a shared workspace for finance, engineering, and procurement to align early, avoiding late-stage surprises or rework.

- Faster Time to Quote: Especially for engineer-to-order or high-mix environments, accurate quoting becomes a competitive edge. Costing tools help generate precise BOM-based quotes faster than ever.

In short, ERP tells you what has already happened. Costing software automates cost calculation, telling you what could happen and how to make smarter choices going forward. It’s not just about tracking costs; it’s about owning them.

Key Features of Cost It Right

1. Costing Management

At the core of the platform, this module enables the granular tracking of cost components, including materials, operations, tooling, packaging, and logistics. It supports both design-stage and procurement-stage costing, enabling proactive cost control.

2. Total Cost Tracking

Tracks the true landed cost of parts and products, factoring in direct and indirect costs like duties, logistics, currency fluctuations, and overheads. Ideal for multi-plant and global sourcing environments.

3. Reports

Auto-generates reports on cost breakdowns, supplier comparisons, sourcing savings, and more. Useful for finance, procurement, and leadership teams to drive data-backed decisions.

4. Integration with ERP

Seamlessly connects with your existing ERP system (like SAP, Oracle, or Microsoft Dynamics) to pull master data (materials, suppliers, rates) and push finalized cost insights back for reporting and forecasting.

5. Master Management

Central repository to manage BOMs, cost elements, currency exchange rates, supplier profiles, and cost templates. Ensures consistency across all costing exercises.

6. Approval Workflows

The built-in workflow engine enables you to define approval hierarchies for cost submissions, quote finalisations, and supplier selections. Ensures compliance and auditability.

7. Amendments

Allows easy revision of cost models and RFQs as per changing inputs, new vendor quotes, material price updates, or revised batch sizes.

8. Vendor RFQ Portal

A dedicated portal for vendors to submit cost quotations. Reduces manual back-and-forth and centralizes supplier communication.

9. Vendor Onboarding

Streamlined supplier registration with pre-set qualification workflows, document submission, and approval protocols.

10. Client RFQ (NFR)

Supports handling of non-functional requirements in RFQs, such as compliance needs, delivery SLAs, or sustainability parameters, alongside core cost data.

11. External RM Indexation

Pulls raw material pricing trends from external sources (e.g., commodity markets) to help cost engineers apply real-world indexation logic during should-costing.

12. Reverse Auctions

Enables reverse bidding from qualified vendors, helping procurement teams drive competitive pricing and save costs in real time.

Pros of Costing Tools

- Detailed, Product-Level Costing

- AI-Driven Forecasting

- Rapid Scenario Simulation

- Improves Speed to Quote

- Enhances Cross-Team Collaboration

Cons of Costing Tools

- Not a Full Business System

- Integration Required

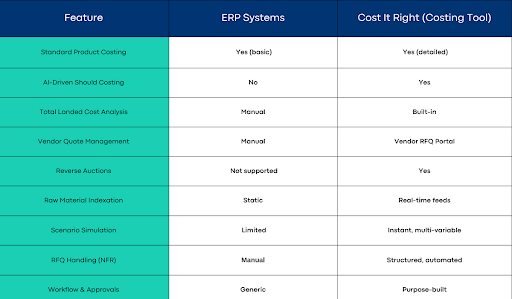

Feature Comparison: ERP vs. Costing Tools

Conclusion

The debate between ERP and costing tools shouldn’t be a matter of “either-or.” Both systems serve distinct yet complementary purposes and when used together, they give manufacturing businesses a serious competitive edge.

ERP is your enterprise-wide record keeper, whereas a costing tool is your strategic cost advisor. So rather than choosing one over the other, forward-looking manufacturers are integrating both. Why? Because visibility without intelligence leads to stagnation, and intelligence without visibility leads to blind spots.

Want to see how our software can help you? Contact us today.