Table of Contents

- The Pain of Manual Quoting (You’ve Felt All of These)

- Manual Quoting vs. RFQ Software: The Straight-Up Comparison

- The Strategic Edge of RFQ Software

- When Manual Quoting Still Works

- What to Look for in RFQ Software

- How to Make the Switch Without Chaos

- Is RFQ Software Right for You?

- Final Word: Your Quoting Process Is Your Growth Engine

In manufacturing, the quoting process is more than just attaching a price tag to a product. It’s a critical business function that influences win rates, profit margins, customer satisfaction, and overall operational efficiency.

Today’s manufacturing environment demands fast, precise, and competitive quotes; delays or inaccuracies can cost you customers and contracts. This is where manufacturers face a key decision: stick with traditional manual quoting methods or invest in RFQ or Request for Quotation software.

This blog provides a detailed side-by-side analysis, helping you choose the method that aligns with your business needs and growth goals.

The Pain of Manual Quoting (You’ve Felt All of These)

If you’ve been in manufacturing long enough, you’ve seen manual quoting in all its glory:

- Digging through old job folders to “find something similar”

- Copying part data from CAD into spreadsheets (and hoping you didn’t miss a digit)

- Emailing suppliers for updated material prices, and waiting days for a reply

- Formatting the quote so it looks professional, even if that means redoing the same document for the 200th time

- Getting approval from a manager who’s in a meeting for the rest of the afternoon

Each step feels small on its own, but together they eat up days. And the longer you take, the colder that lead becomes.

Worse, the process relies heavily on tribal knowledge, which includes the little details known only to one or two people. If they’re on vacation or out sick, the whole quoting pipeline grinds to a halt.

And let’s not forget mistakes. Manual entry leaves room for typos, incorrect formulas, or outdated pricing without realizing it. A single wrong decimal in a material cost can mean a quote that’s either too high to win or so low it erases your profit.

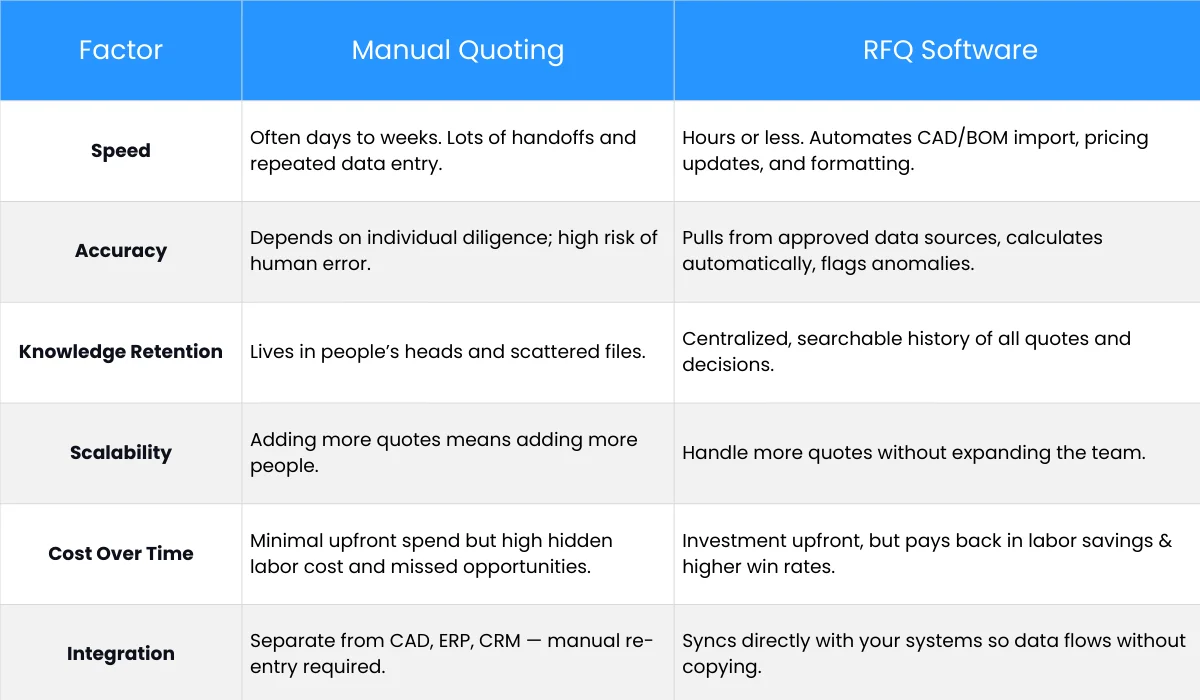

Manual Quoting vs. RFQ Software: The Straight-Up Comparison

Key takeaway: Although manual quoting may seem “free” since you’re not paying for quoting software, the real costs in time, lost deals, and stress are significant.

The Strategic Edge of RFQ Software

Let’s make this practical. Why do manufacturers who switch to RFQ management software rarely go back? Because the difference shows up in measurable results.

1. Quoting Speed Becomes a Weapon

One sheet metal shop used to take 4–5 days for an average quote. After implementing RFQ software, they could turn most quotes in under 6 hours. That meant they could respond to twice as many opportunities and win more jobs.

2. Accuracy Without Extra Effort

With automated supplier price updates and built-in labor calculations, you can stop chasing spreadsheets for last-minute checks; the numbers are already right.

3. Knowledge Stays in the Business

With manual quoting, if your senior estimator retires, so does a decade of pricing wisdom. The request for quotation software stores insights, past jobs, notes, and customizations, making them available to everyone.

4. Tangible ROI

Let’s say your average project is $50,000. If faster quoting helps you win even two extra projects a year, that’s $100,000 in additional revenue. In most cases, that alone covers the annual software cost, before counting the labor savings.

Also Read: Why Procurement Automation Software Needs Built-In RFQ & Onboarding

When Manual Quoting Still Works

To be fair, RFQ software isn’t always the right move. You might be fine with manual quoting if:

- You send fewer than 10 quotes a year.

- Your pricing and product mix are extremely stable.

- You have low complexity jobs and repeat customers with set agreements.

- Right now, the budget just can’t cover new software.

Even if you think quotation software isn’t worth it right now, keep watching how business conditions change. Sometimes, things shift quickly, such as receiving a sudden surge of quote requests or a major customer demanding faster turnaround. These changes can quickly make RFQ software worth the investment.

What to Look for in RFQ Software

If you’re considering making the move, don’t get distracted by flashy dashboards you’ll never use. Focus on features that actually solve your quoting pain points:

- CAD & BOM Integration: No retyping part dimensions and specs.

- Supplier Database Links: Material prices update automatically.

- Collaboration Tools: Engineering, sales, and procurement can work in the same system.

- Analytics & Reporting: See how long quotes take, your win rate, and where you lose margin.

- Customizable Templates: Professional proposals without reformatting every time.

How to Make the Switch Without Chaos

Switching from manual quoting to RFQ software is less about technology and more about change management. Here’s a roadmap that works:

- Pinpoint Your Pain Points: Don’t just say “we’re slow.” Figure out if delays come from supplier responses, data entry, or internal approvals.

- Run a Pilot: Test the software on a small subset of quotes. Track how much time it actually saves.

- Train for Benefits, Not Just Features: Demonstrate to the team how the tool alleviates their pain points, rather than just how to use its features.

- Measure & Share Wins: If you cut quoting time by 50% or win a project because you were faster, tell everyone.

- Roll Out Gradually: Expand usage once the team sees the value.

Is RFQ Software Right for You?

If you answer “yes” to most of these, the move probably makes sense:

Final Word: Your Quoting Process Is Your Growth Engine

The quoting process isn’t just admin; it’s the starting line of every project you’ll ever win. If you can quote faster, more accurately, and with less stress, you put yourself ahead of the competition before the job even starts.

Manual quoting can work, but it has limits. RFQ software removes those limits, giving you speed, accuracy, and scalability that manual methods just can’t match.

If you’re not sure whether it’s time to switch, start small. Run a pilot. Compare the numbers. In most cases, the results will decide for you.